Introduction

Manufacturing the products is very costly as well as a complex process for businesses that are not having the right tools, resources, and equipment to develop their quality products. In the current time, machine learning has become more popular in producing and assembling items, helping in cost reduction and time reduction of the production of a particular product. As a matter of fact, around 40% of the potential value that can be created using analytics today comes from machine learning techniques.

It has been noticed that from the last 5-6 years exceptional technologies can help build rapid and robust models that drive a lot of functional improvements.

Benefits that ML provides

Here are some ways through which machine learning is positively impacting the production process and providing benefits to it:

Improving the process:

There are three aspects of business namely operation, production, and post-production. Most of the manufacturers are successful in adding machine learning into these three aspects of their businesses. For example – Fanuc is a Japanese manufacturer of robotics and automation technology that included the machine learning process. It uses deep reinforcement learning that is a machine learning solution. Also, it enables and helps the robots to learn new skills very quickly and effectively. It doesn’t need precise and complex programming anymore.

Product Development:

Data has proved to be a very important entity as it brought nig opportunities for all the manufacturing companies in their product development process. It helps their businesses to understand customers and their needs and successfully meet their demands. This way, it helped in the overall development of a new and better product for the customer base. This data is valuable as the manufacturers are now able to create a product with an increasing customer value and it reduces the risks that are connected with the introduction of some new products to the potential market. Several actionable insights are taken as they help in strengthening the company’s decision-making process while planning, strategizing, and then modeling the final product.

Robot:

Robots are machines that can bring a lot of change in manufacturing. They are very helpful in performing all the daily routine tasks that are complex or too dangerous for humans to perform. Manufacturers these days put more money into robotizing so that they can meet their demands and reduce human errors. These machines end to contribute a lot to the best quality product manufacturing. Every year, the products come to the baseline in order to enhance the product lines.

Security:

Machine learning has developed such platforms that have made mobility a lot more secure in a company. The machine learning algorithms make their processes secure and also empower business innovation along with ensuring the smooth development of devices, mobile apps, etc, and data is protected across the organization. It gives on-device security and repairs device and network threats on any device.

Quality Control:

Machine learning plays a vital role and acts as a pillar in enhancing the overall quality of every manufacturing process. Its deep-learning neural networks help in the performance, weakness, availability, and quality of assembly equipment of the machine. For example – Siemens is using a neural network so that they can monitor their steel manufacturing and improve their overall efficiency. These kinds of companies invest a lot in machine learning to improve the quality of their operations.

Supply Chain Management:

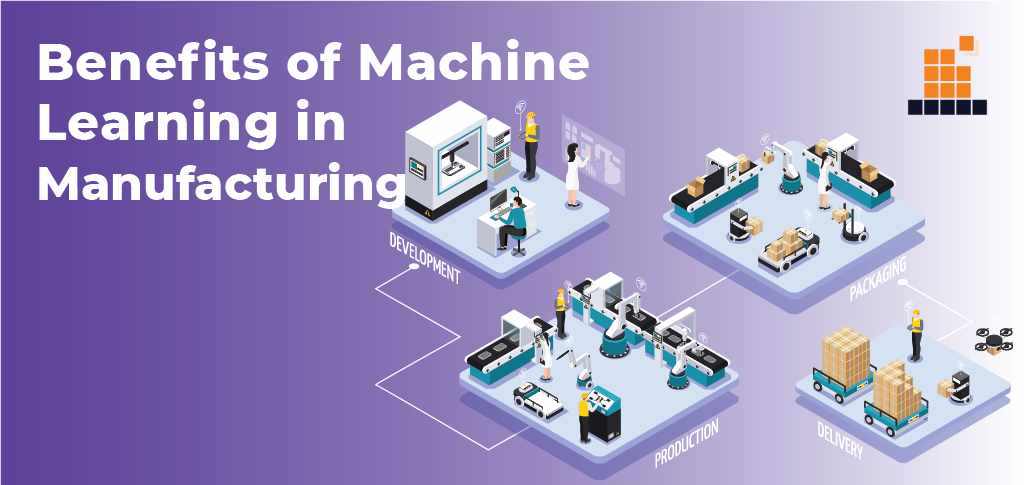

Machine learning technology lends a helping hand to companies. It helps them so that they can maximize their value by improving their inventory management, supply chain management, logistics process, and asset management. It is better if machine learning, IoT, and artificial intelligence integrate. They will then ensure the high-level quality of products. The manufacturers today are finding new ways to combine all these emerging technologies with supply chain visibility, inventory optimization, accuracy, and asset tracking. The machine learning development companies and organizations have developed a supply chain management (SCM) suite. It can monitor each and every step of manufacturing, delivering, and packaging.

Summarizing the whole scenario

It is very obvious now at this point that the manufacturing industry is a technically advancing sector. The advantages of the adoption are increased productivity, reduced equipment failures, better distribution, and the introduction of enhanced products. Looking at all these benefits of machine learning in manufacturing, manufacturers around the world have already started investing a large sum of amounts in machine learning solutions. They did it for better efficiency and to empower their processes. The widespread adoption of these solutions will take place slowly. It’s taking place and in a few years, we will definitely see numerous companies leading the way to a smarter way of manufacturing the products we generally use in our life.

Robots and machine learning will transform the manufacturing industry. But, the manufacturing workforce needs to be reskilled to work alongside the newly developed work machines. The machines being used presently need maintenance which increases the downtime and isn’t cost-efficient. Sometimes the approach also seems wrong as the actual problem still hasn’t been solved which was leading to system failure. Getting accurate insights requires a long time. It is not a day’s task and takes years to address the real problem which leads to system failure. Machine learning can be a key as it can alert operators of time before. Also sometimes it can also avoid unplanned downtime of machines which would save a lot of time. The algorithm developed through machine learning will be a huge transformation in the manufacturing sector. It would benefit a lot the manufacturers.